A microblog series on the HubSizer® and MarketSizer® tools from New Venture Advisors

Are you a food hub that sees surges from your farmers in broccoli in the summer or beets in the fall? Have you been trying to figure out how to take advantage of a big glut of produce during the growing season in order to provide more products to your customers year round?

Our final microblog in the Toolsite Spotlight series looks at the Frozen Processing HubSizer® tool to estimate the facility size needed and breakeven throughput, revenue and utilization for blast and cryogenic IQF freezing processes. Individually quick-frozen (IQF) processing is an increasingly popular way to take advantage of the large volumes of fresh produce that come in during the height of the growing season and preserve it for institutional and wholesale customers that would like to serve it year-round. However, IQF machines are expensive to purchase and operate, so understanding what it takes to invest in one is important for any business to thrive.

Today we’ll walk you through a fictional example of an Illinois Food Hub that uses the Frozen Processing HubSizer® to get a sense of what it would take to launch a frozen processing service within their existing facility including the estimated start-up costs and the product volume needed to make it profitable.

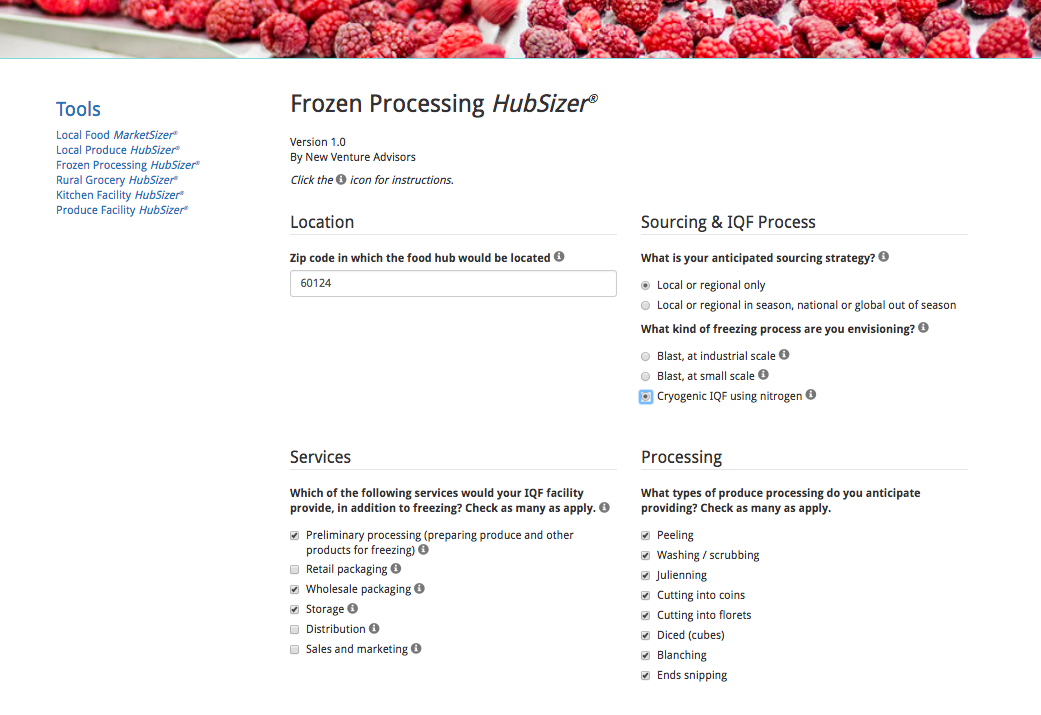

Enter the NVA Toolsite and click on the appropriate tool to be taken to the input page. Input the numbers for the type of frozen processing your food hub plans to do:

This Food Hub is located in central Illinois and plans on sourcing local or regional products only. The operators are interested in exploring cryogenic IQF processing using nitrogen. For Services, they select preliminary processing, wholesale packaging and storage because they already provide many of these services in their existing facility. They plan to do ALL types of produce processing so they select each option under Processing.

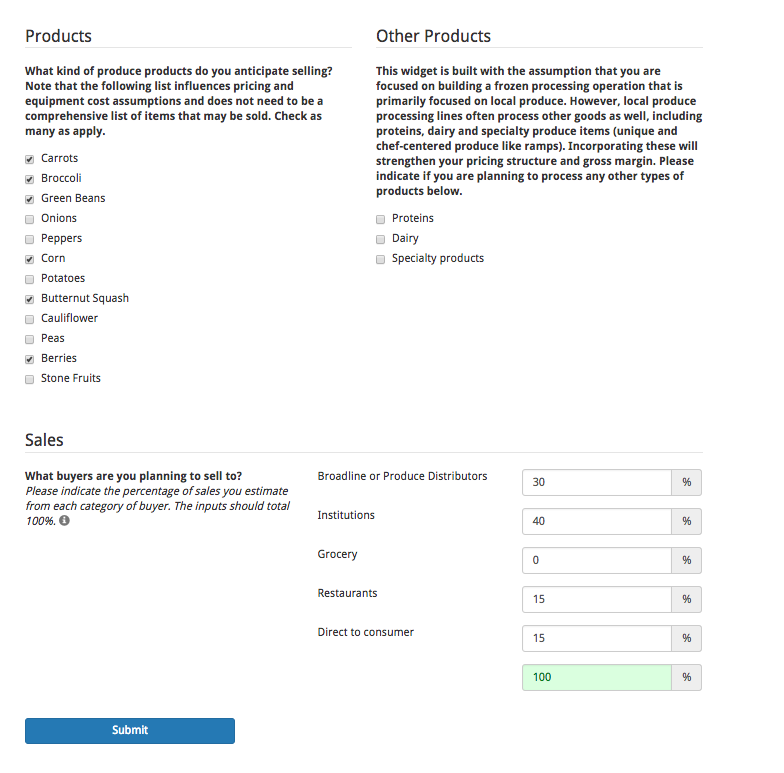

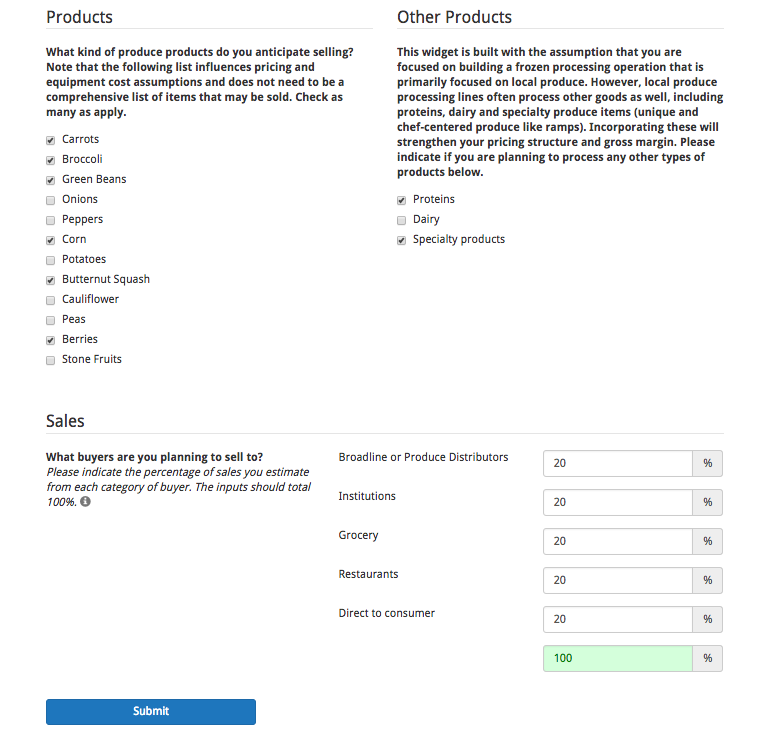

Further down the page, the tool asks for inputs on types of products the Food Hub plans on selling and the types of customers they anticipate serving. This Food Hub is focused on institutional and broadline distributor buyers, so their product selection reflects this (these buyers tend to want processed veggies like carrot coins, broccoli florets, diced squash etc) as does the majority percentage of anticipated sales. They also hope to sell to a smaller number of restaurants and individual consumers.

They input these estimates and hit Submit!

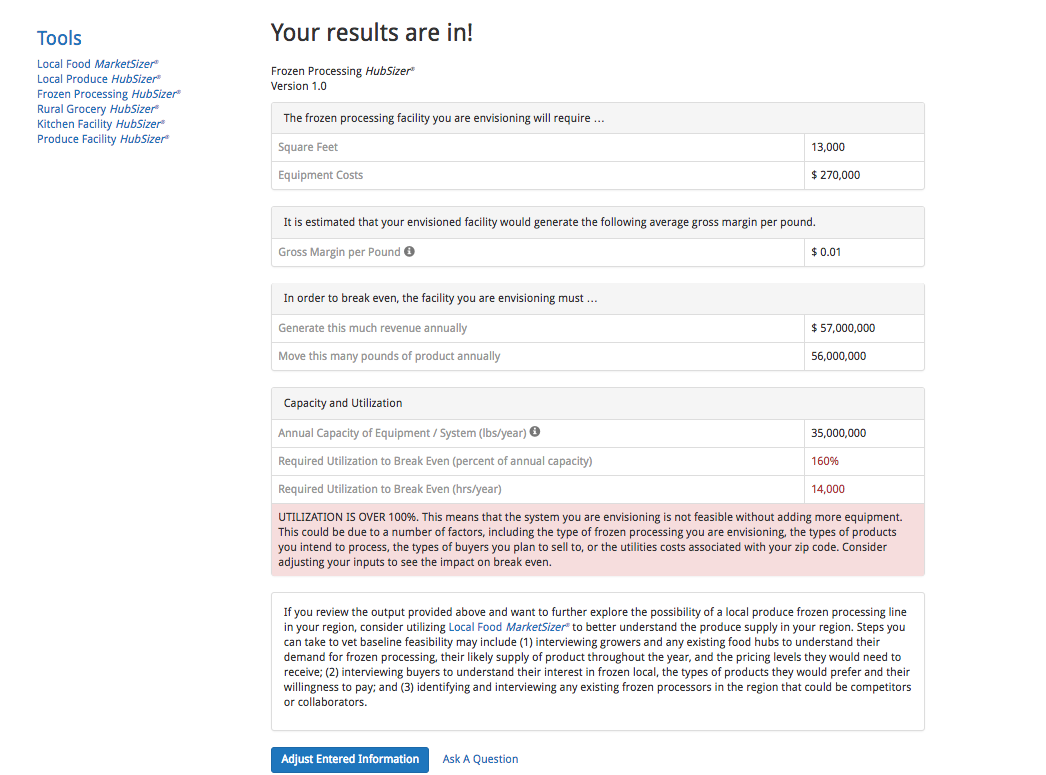

The results show a pretty tough outlook based on these initial inputs. The top line estimates space required to house the type of equipment selected, which in this example is 13,000 square feet — this off the bat is a non-starter since the Food Hub is currently only 5,000 square feet and they do not plan on such a big expansion. The gross margin based on the types of customers and products selected is just 1 cent per pound, which means that in order to break even, the facility would need to generate $57 million in annual revenue. These inputs result in the red warning under Capacity and Utilization which points out that the equipment would need to operate at a capacity greater than 100%, which is not feasible. Given this low margin structure, even if more equipment was acquired to increase capacity, the operation’s cost structure would increase, likely resulting in a new break even that is also not feasible.

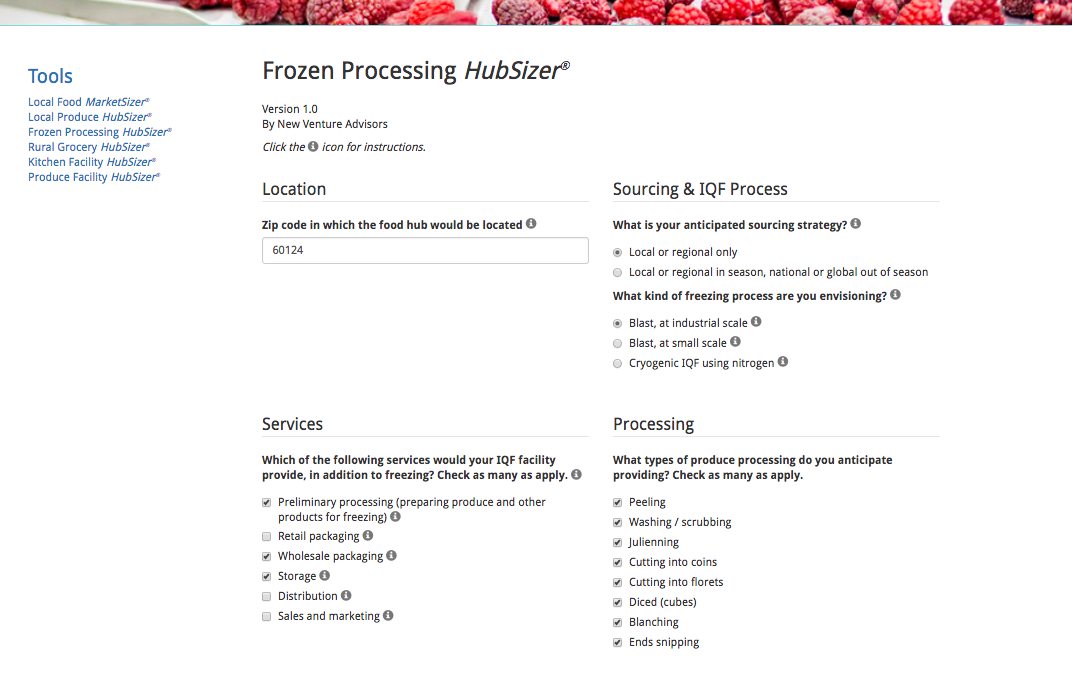

The Illinois Food Hub had selected cryogenic IQF using nitrogen which is an extremely expensive option. What would the numbers look like if they switched their selection to batch frozen processing at an industrial scale? They also selected ONLY fresh produce as their products to process, but often IQF equipment can be used on a diverse array of foods, some with higher margins. What would the results look like if proteins was selected as an additional product? There is plenty of beef/cattle supply in Central Illinois. Perhaps nearby farmers want to add value to their meat by freezing it? They hit Adjust Entered Information and go back to the tool’s input page to make some adjustments to their numbers:

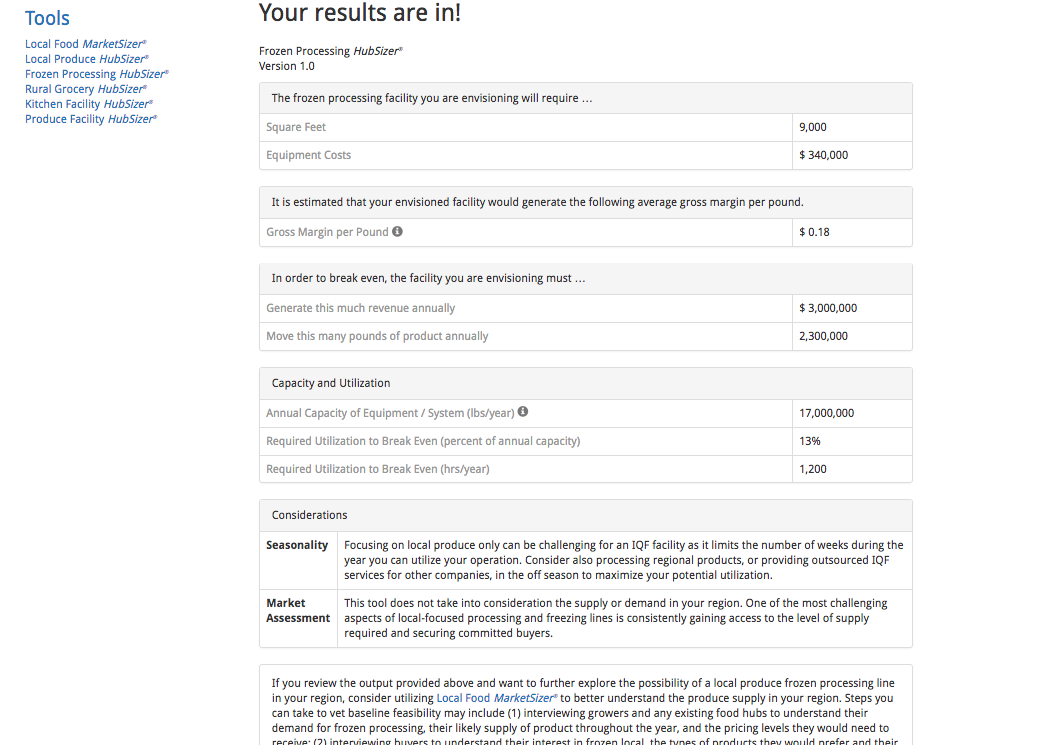

Finally, the Food Hub had selected the most price sensitive customers to sell to: institutions and distributors. If they diversified their customer base, they might be able to get higher overall margins. They re-submit and see the results:

The results are looking much better! While the facility still needs to be an estimated 9,000 square feet, that expansion may be more manageable than the initial result of 13,000 square feet. The margin has increased to 18 cents per pound and most importantly, the required utilization to break even is 13%, which is fairly low. These few adjustments to the assumptions using the Frozen Processing HubSizer® suggest that adding frozen processing capacity to this food hub could become a reality! It should be noted that having ample supply of local produce (and local protein) is a major factor in determining the viability of adding an IQF to your food hub. Consider utilizing the Local Food MarketSizer® to better understand supply in your region.

This concludes the sixth and final microblog in NVA’s Toolsite Spotlight series! To read the previous blogs on each MarketSizer® and HubSizer® tool, just head back to our blog. If you have any questions about how to use the tools or want to pursue next steps based on the outputs, don’t hesitate to reach out to us at New Venture Advisors [email protected]