A microblog series on the HubSizer® and MarketSizer® tools from New Venture Advisors.

Over the past few weeks we’ve explored how to analyze a market for local food with the Local Food MarketSizer® tool; investigated how to turn a grocery store into a food hub with the Rural Grocery HubSizer® tool; and most recently we looked into the feasibility of creating a food hub with the Local Produce HubSizer® tool.

Today, we’ll explore a similar scenario as last week’s but with the Local Produce HubSizer® tool. This tool is designed for any individual or team that has access to an existing building or space, and is curious as to whether or not the site could be an effective location for a Local Produce Food Hub. This tool provides the maximum revenue your site could generate as a food hub, and the maximum volume of produce it could move. It also provides an assessment of whether or not a food hub in your identified location could break even and if so, what throughput levels it would need to achieve in order to to do so. On the other hand, the Local Produce HubSizer® (which was explored last week) outputs how much square footage is needed in order for an envisioned food hub to break even, and is therefore intended for those who have no site in mind, and are open and able to select their food hub site based on the analysis they conduct.

The tool asks you to input the square footage of the space you have access to, the monthly amount you will be expected to pay per square foot (recognizing that you may have free access to the space or significantly reduced rent obligations), and basic business model elements of the food hub you envision operating out of this space. These inputs enable the tool to generate the space’s maximum capacity, break even potential, and break even utilization.

For this post, we’ll see how this tool would work using a scenario we’ve seen multiple times in the course of our work.

Let’s say that I am an Executive Director of a food bank in a small metropolitan area in Washington state.

My food bank successfully serves dozens of food pantries across my region. We have also improved our operations and our relationships with our satellite food pantries in a way that has allowed us to move product through our 10,000 square foot warehouse more quickly than we have in the past. This is great news!

But it also means we no longer need 3,000 square feet of our massive facility. This excess space is currently dry storage, but we know it would not be a major investment to convert it to cold or frozen storage. During a recent board meeting, an idea was brought up to see if and how this excess space could be utilized to generate a new, earned revenue stream (which would be incredibly helpful as our funding sources are getting squeezed each year!). One opportunity we are now exploring is to retrofit the space as a frozen storage unit and rent it out to a local facility that produces frozen meals. An alternative opportunity is to retrofit the space for cold storage and to operate a food hub aggregating and storing local produce from it. This second option is much more appealing to our leadership team and staff because it aligns well with the food bank’s mission by improving opportunities for local agricultural producers and bringing community members healthy, fresh produce.

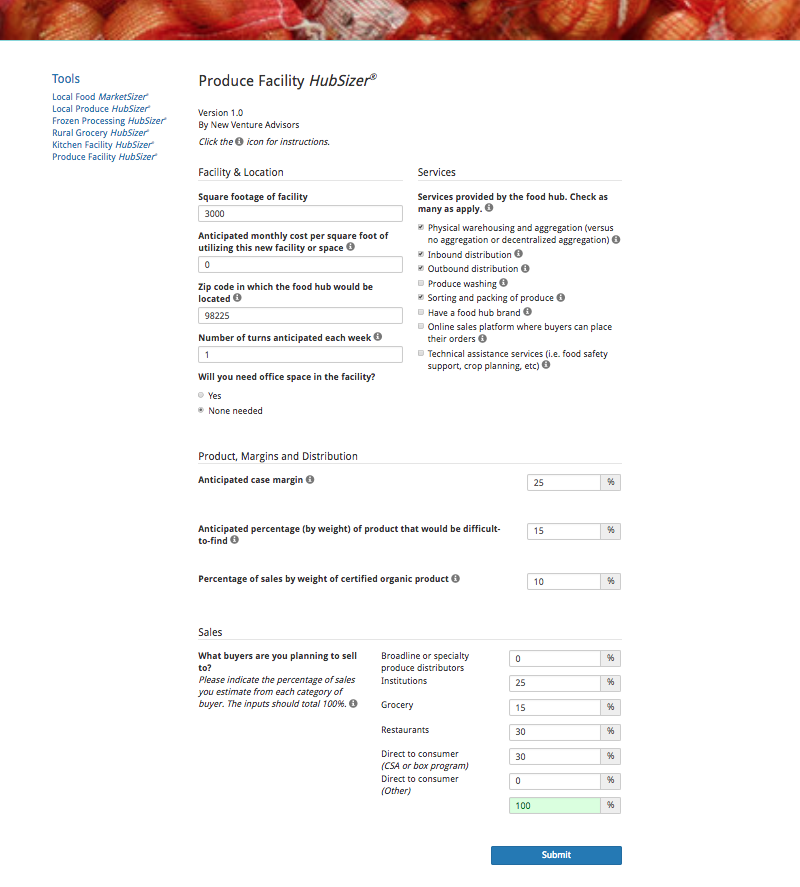

The Produce Facility HubSizer® tool is perfect for my scenario! To access it, I head over to the NVA Toolsite, log in, and click the appropriate tool. From there I am taken to a familiar page (if you read last week’s microblog post, it’s very similar) and input our numbers:

The first question asks the square footage of my facility. Although my overall food bank is 10,000 square feet, I know only 3,000 square feet is available for a new operation so I input 3,000 here.

To simplify the example, I input “0” as the anticipated monthly cost. Although we do have some occupancy costs for the facility, I know these will be incurred regardless of whether we use this space in a different way, so “0” is a straightforward way to find out the incremental opportunity of a food hub.

In the first year, I anticipate that a food hub can likely achieve one ‘turn per week,’ meaning we’ll receive produce from farmers, accept and fulfill orders once per week.

The next question asks what services the hub will provide. I haven’t thought through a potential food hub in this level of detail yet, but this question helps me understand what I need to better flesh out if I were to run one out of my food bank. For now, I anticipate that we can provide physical warehousing, inbound and outbound distribution (given our existing fleet of delivery vehicles), and sorting and packing of produce.

The tool then moves on to the Product, Margins, and Distribution section. I enter 25% for the case margin (I’d like to take less from the farmers but am unsure what is appropriate in this situation – something else to be researched if and when we explore this idea further). Additionally, I plan to source 15% ‘unique products’ and 10% organic produce.

I then get to the Sales section, which helps me understand what I need to know about the market landscape and the demand/buyer base for local food in my region. I anticipate that nearby broadline distributors would not be the right buyers for us to work with. So I instead focus on institutions (schools, hospitals), grocery stores, restaurants and a direct-to-consumer CSA.

Then, I hit Submit!

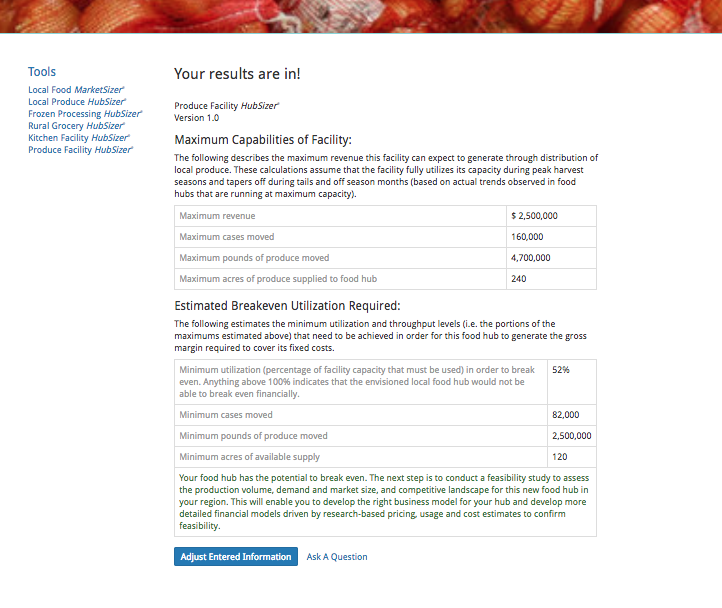

The results in the first section show the Maximum Capabilities of the facility, which is not the same as what we have to achieve to break even. These numbers show that, at full capacity, operating the maximum amount of hours and days possible, the food hub could generate $2.5 million in revenue with 160,000 cases moved per year. This equates to 4.7 million pounds of produce moving through the hub, requiring 240 acres of farmland. This is the max capacity, remember.

Now, the next section estimates the Breakeven Utilization Required. These numbers show how much money the hub would need to make and produce it would need to move in order to just break even. The results show that the hub would need to be utilized 52% per year and move a minimum of 82,000 cases of produce requiring 120 acres of available farmland. While the results state that this food hub has the potential to break even financially, the utilization rate may feel a bit high (but I don’t know! Need to explore further…) and may be difficult to achieve, plus that’s not even turning a profit.

Additionally, we’d need to ensure we’d have access to that much farmland and farmers who can provide such volumes. In short, based on these numbers, we’d still need to do a feasibility study to understand the full landscape of the food system in which my potential food hub would operate. But the results are promising, especially since the facility for the food hub has the potential to break even with room to turn a profit.

(Photo courtesy of Bob Benensen/FarmilyFarmed)

Next week, we’ll explore the Kitchen Facility HubSizer® tool and how to analyze a potential commercial kitchen space!